THE LOUD PEDAL WAS JUST THE BEGINNING…OR END?

Twas a few days before christmas and the mustang hadn’t moved, the build was far from over and the car was running smooth. That’s about as far as I go into holiday rhymes, my holiday spirit seems lacking this year but I’m still happy to see all the cheer, lights and trees around and happy people enjoying the holidays. A week ago I released “The Loud Pedal” my 3 week long thrash to make my 1968 Mustang go from a fresh and almost barren chassis to a running and driving car.

It started out simple, I wanted to make all 3 pedals function and connected to what they operate. Throttle, Brake, and clutch…easy right? How about the worst case of “while you’re in there” (theme of entire car) ever! Let’s be honest the while you’re in there thought process is how this car went from a mosaic of bondo on rust to now being a solid chassis that won’t twist or disintegrate on turn 1 at Mission Raceway. The process was already underway as I had a closed and functioning brake system so I could check one off the list. Next was the clutch pedal, that would require the fabrication of a bracket to mount it as well as hooking up BMW lines through the firewall. To connect the rod end to the mustang pedal I simply welded a nut to the pedal, threaded a bolt through the rod end and hooked it all up. This is where the plans to hookup the rest went sideways.

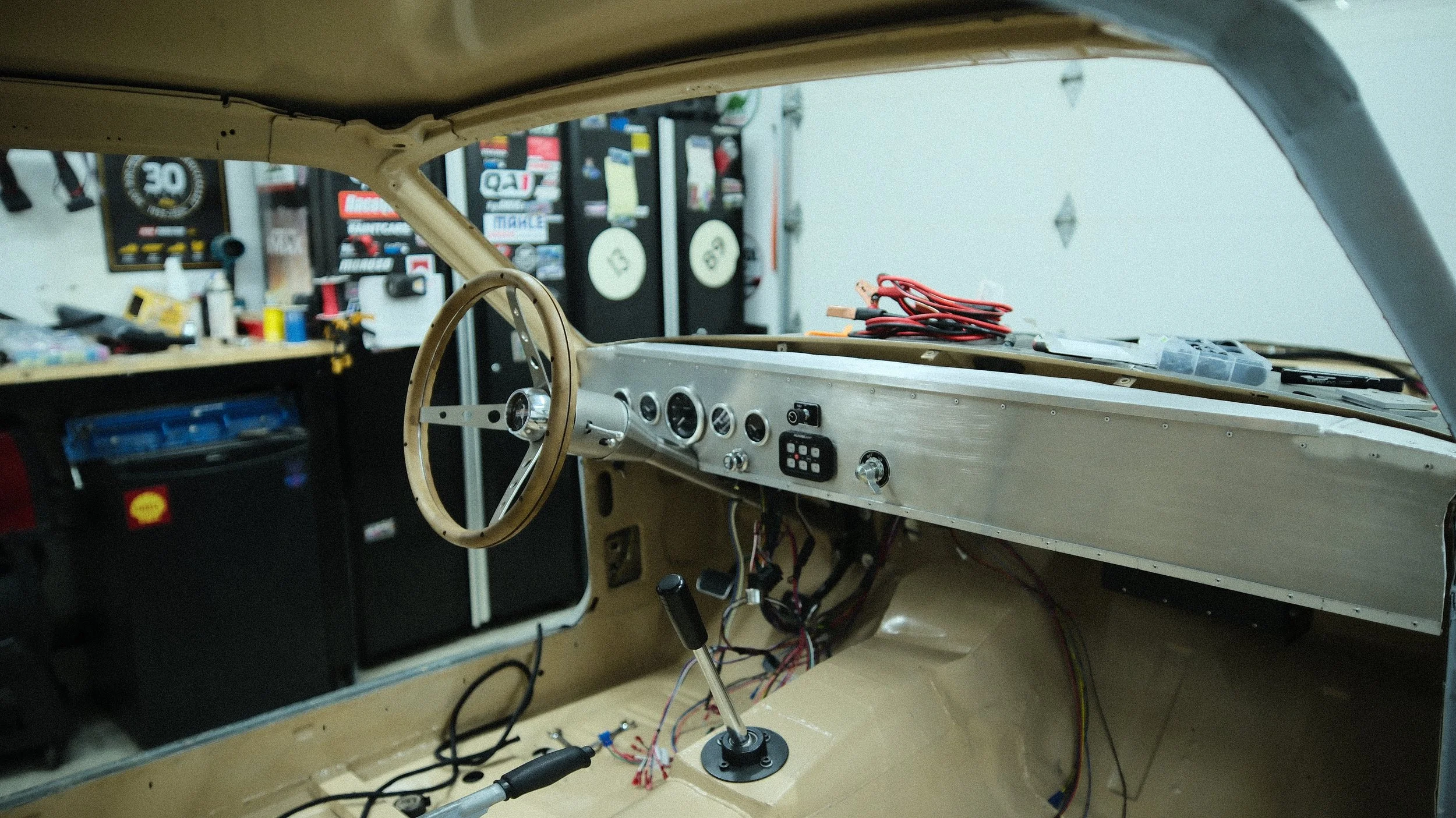

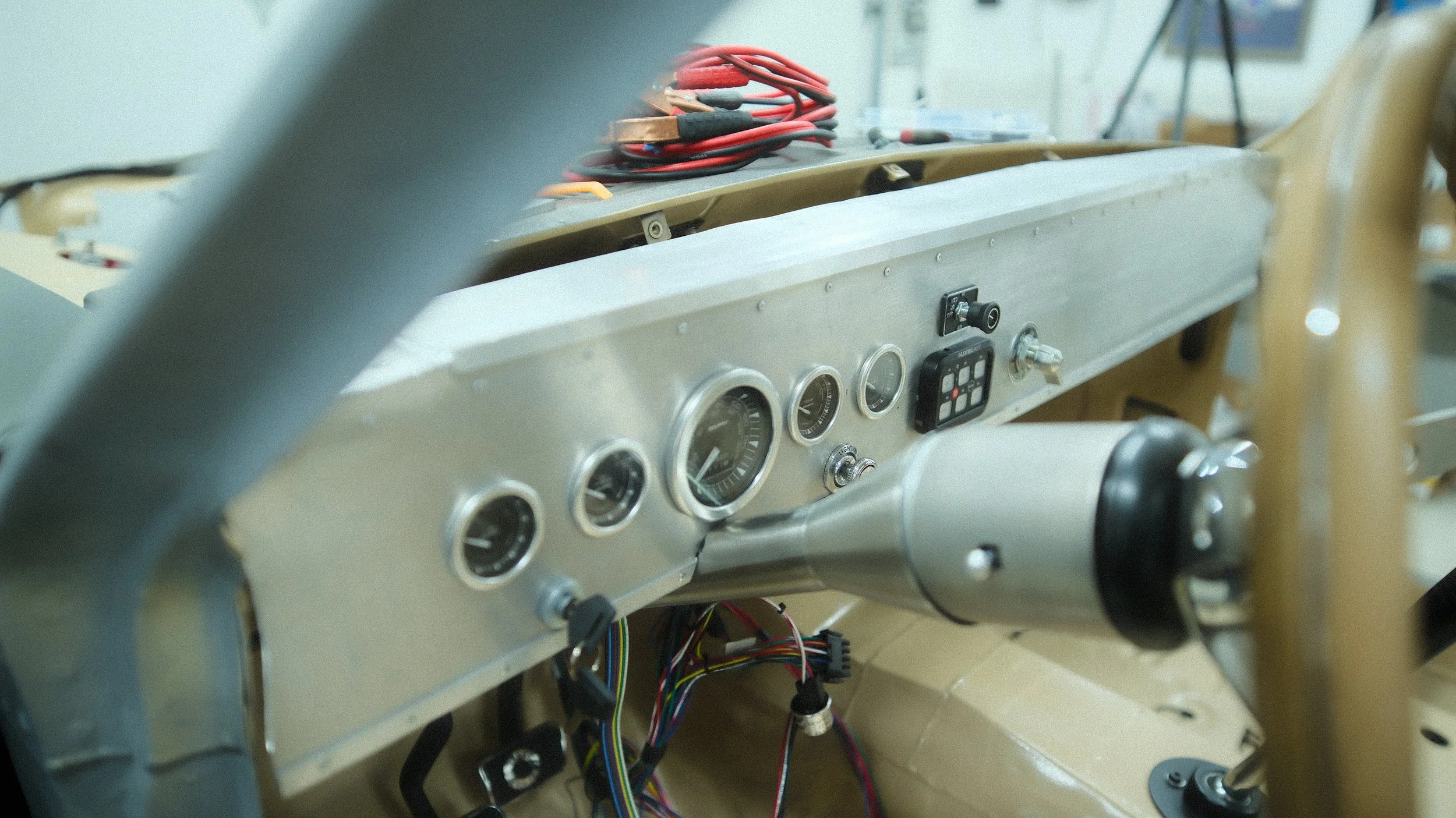

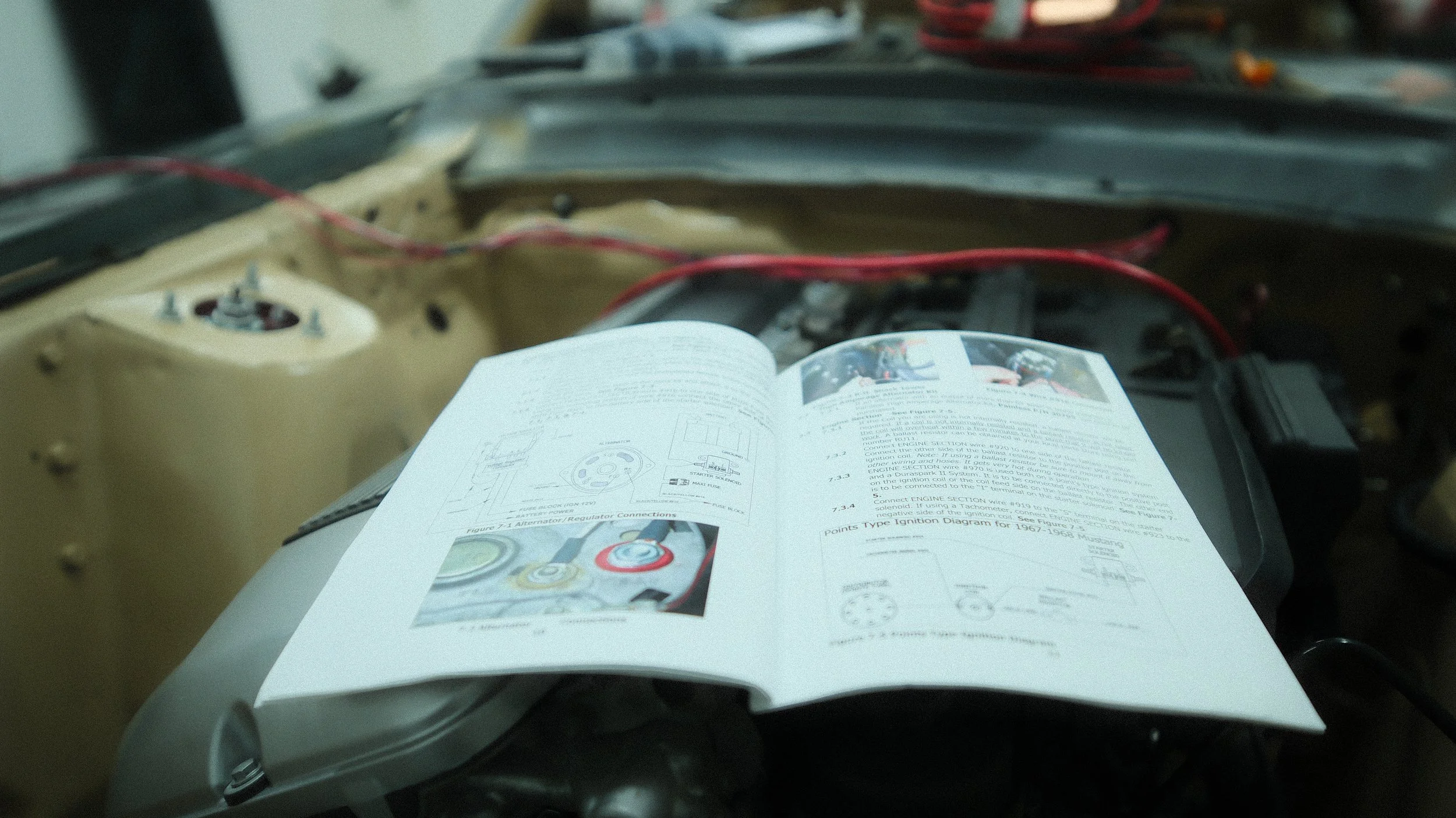

I had everything ready to bolt in and realized I needed to run all the wiring to make sure everything would clear the pedals as well as the wiper arms under the dash of the car. On classic mustangs the wiper assembly is inside the car under the cowl and makes for a nasty wire slicer should any 16 gauge copper wire get in the way of the pinch points. Indeed yes, I almost experienced that action in real time but I luckily I remembered the lack of a ziptie in a key location. So where was I? oh yea I had to completely finish wiring under the dash, which in turn meant I should just finish the wiring completely…see how fast it spirals? That right there is the mental process that inadvertently gets project cars done, you just have to commit. I’ve run completed harnesses and hooked up basic 12v circuits with relays etc, but not on this scale. A painless wiring direct fit harness helped my tiny brain make sense of the layout and schematics but it was no small task.

About a week and a half of full days, some as long as 14-16 hours and I finally got the wiring squared away and functioning to where I was confident it wouldn’t catch fire and burn the car to the ground. Lights functioned, fuel pump, gauges, wipers and all the accessories needed. The major hurdle was behind me and I could focus on hooking the motor back up and making the car ready to move, FINALLY!

Lights, camera, no action… The wiring was complete(mostly) and ready for the ECU and engine to be hooked up and fired again. After spending a few hours with a bag of zipties and clips everything was connected, and I was able to fire the engine up on key for the first time. Felt pretty damn good I gotta say, before I had just mickey moused everything with gator leads and touching wires together. It felt real, it felt alive and read to drive, I just needed to get a cooling system hooked up.

I decided to ditch the OEM BMW radiator setup and ended up buying a universal aluminum rad and mounts to mate to the M54. This is where you’d want to turn to the video on my Youtube channel for more details, as I was running low on time to get the car mobile and was concentrating on making it happen. I encountered some leaks with my home made heater core lines and fittings, but the cooling system did it’s job just enough to run the car for a bit. After slamming the driveshaft home and extending the shifter linkage, it was ready to roll.

I’ll save you the long drawn out literary imagery, I finally got to drive my Mustang out of the Garage with BMW power!!! The only glaring issue on the maiden voyage was the front passenger tire rubbing the fender/valance on sharp turns. Other than that it actually felt half decent! The front coils are too stiff for my liking bu they do function, and the suspension cycled and felt free. That means that all the hours of planning, measuring and fabricating effin worked! There is still a tonne of work to do, glass is slated to go in the front for early January and there is still stuff to create and bolt to the car. For now, I’m going to enjoy the holiday purgatory and make more plans for 2026.

See you guys on the road!